Transmission systems are the unsung heroes of modern automobiles. While engine performance grabs the headlines, these intricate components ensure that power is effectively transferred to the wheels. At the heart of this system lies a vital component – the tranny tube. Despite its humble appearance, this flexible conduit plays a crucial role in your vehicle’s health and longevity. In this comprehensive guide, we’ll delve into the world of tranny tubes, exploring their purpose, types, selection, and proper usage.

What is a Tranny Tube?

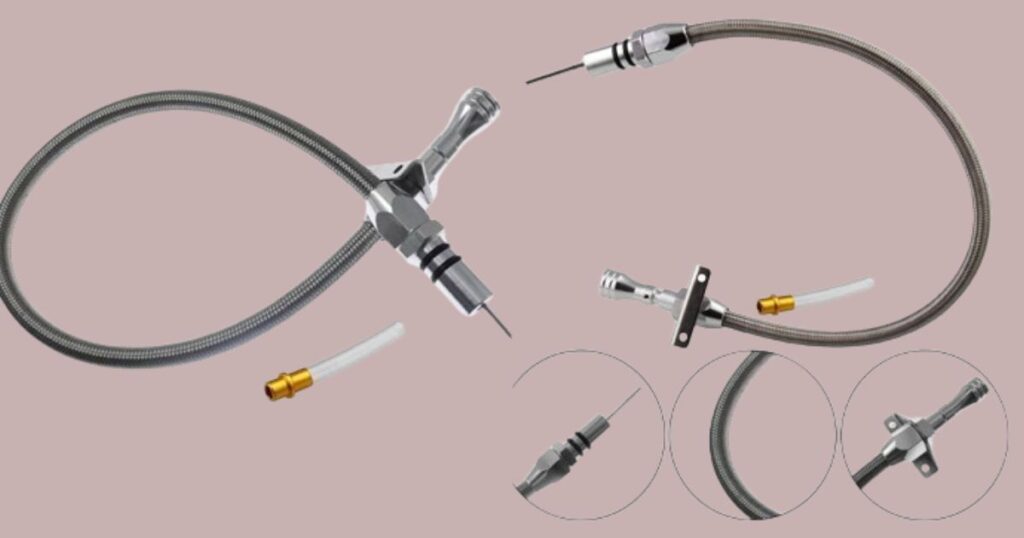

A tranny tube, short for transmission tube, is a flexible tube designed to facilitate the circulation of transmission fluid within a vehicle’s transmission system. Constructed from durable yet pliable materials, these tubes act as conduits, allowing the free flow of fluid while accommodating the inevitable movement and vibration of the engine.

The primary function of a tranny tube is to prevent leaks and ensure proper lubrication, which is essential for the smooth operation of the transmission. Without these flexible tubes, the rigid metal lines commonly used in transmission systems would be prone to cracking or breaking due to the constant stress of engine movement, potentially leading to costly repairs or even complete transmission failure.

The Purpose of Tranny Tubes

Tranny tubes serve a vital purpose within the transmission system: they enable the efficient circulation of transmission fluid while accommodating the inherent movement and vibration of the engine. This dual role is crucial for several reasons:

- Fluid Circulation: Transmission fluid acts as a lubricant, cooling agent, and hydraulic medium, facilitating the smooth operation of the transmission’s intricate components. Tranny tubes ensure that this fluid can flow freely throughout the system, reaching all the necessary areas.

- Heat Dissipation: During operation, the transmission generates significant heat due to friction. Tranny tubes aid in heat dissipation by allowing the hot transmission fluid to circulate and transfer heat away from critical components.

- Vibration Absorption: Engines are not static entities; they move and vibrate constantly during operation. Tranny tubes are designed to absorb and accommodate this movement, preventing the rigid metal lines from cracking or breaking under stress.

- Leak Prevention: Perhaps most importantly, tranny tubes help prevent transmission fluid leaks. Leaks can starve the transmission of essential lubrication, leading to premature wear and potential failure.

By fulfilling these critical functions, tranny tubes contribute to the overall performance, efficiency, and longevity of your vehicle’s transmission system.

Functions of Tranny Tubes

While the primary purpose of tranny tubes is to facilitate fluid circulation and prevent leaks, these unassuming components serve several crucial functions within the transmission system:

- Fluid Transfer: Tranny tubes act as conduits, enabling the transfer of transmission fluid from the pump to various components, such as clutches, bands, and gears.

- Heat Dissipation: As transmission fluid circulates through the system, it absorbs heat generated by friction. Tranny tubes play a role in this heat dissipation process by allowing the hot fluid to flow away from critical components.

- Vibration Absorption: The flexible nature of tranny tubes allows them to absorb and accommodate the constant movement and vibration of the engine, preventing rigid metal lines from cracking or breaking under stress.

- Leak Prevention: By providing a sealed, flexible connection between various transmission components, tranny tubes help prevent transmission fluid leaks, which can starve the system of essential lubrication.

- Improved Accessibility: Tranny tubes enable neat routing of fluid lines, making it easier to access and perform maintenance or repairs on the transmission system.

Understanding these essential functions highlights the critical role that tranny tubes play in ensuring the smooth, efficient, and long-lasting operation of your vehicle’s transmission.

Features of a Tranny Tube

While tranny tubes may appear simple, they possess several key features that enable them to perform their vital functions effectively:

- Flexible Construction: Tranny tubes are designed to be flexible yet durable, allowing them to accommodate engine movement and vibration without cracking or breaking.

- Heat and Chemical Resistance: Transmission fluid can reach high temperatures, and tranny tubes must be able to withstand this heat without degrading. Additionally, they must be resistant to the chemicals found in transmission fluids.

- Abrasion Resistance: Over time, tranny tubes can rub against other components or surfaces, so they need to be resistant to abrasion to maintain their integrity.

- Tight Sealing Capabilities: To prevent leaks, tranny tubes must be able to create a tight seal at their connection points, ensuring that transmission fluid remains contained within the system.

- Long Service Life: High-quality tranny tubes are engineered to withstand the harsh operating conditions of a transmission system for an extended period, reducing the need for frequent replacements.

By combining these essential features, tranny tubes contribute to the overall reliability and longevity of your vehicle’s transmission system, ensuring smooth operation and minimizing the risk of costly repairs or failures.

Availability

Tranny tubes are widely available as aftermarket parts, making it easy for vehicle owners and mechanics to obtain replacements when necessary. You can find them at:

- Automotive Parts Retailers: Major auto parts chains, such as AutoZone, NAPA, and O’Reilly Auto Parts, typically carry a wide selection of tranny tubes from various manufacturers.

- Dealerships: If you prefer OEM (Original Equipment Manufacturer) parts, your local dealership can order tranny tubes specific to your vehicle make and model.

- Online Retailers: E-commerce platforms like Amazon, RockAuto, and specialized online auto parts stores offer a convenient way to purchase tranny tubes, often with competitive pricing and convenient shipping options.

- Local Mechanics and Repair Shops: Many automotive repair shops and mechanics keep a stock of common tranny tube sizes and materials, ensuring quick access for replacements during maintenance or repair jobs.

Regardless of where you choose to purchase your tranny tubes, it’s essential to ensure that you select the correct size, material, and specifications for your specific vehicle and transmission system.

Read Also: Installing Lap Dat Camera SLS Telecom

Is a fluid replacement for your car necessary?

Transmission fluid plays a crucial role in lubricating, cooling, and protecting the intricate components of your vehicle’s transmission system. Over time, however, this fluid can degrade due to heat, friction, and contaminants, compromising its performance and potentially leading to transmission issues.

One of the telltale signs that a transmission fluid replacement may be necessary is the presence of debris or sludge within the system. As transmission fluid breaks down, it can create deposits that clog tranny tubes, restricting fluid flow and potentially causing leaks.

Routine transmission fluid changes and flushes are recommended by most vehicle manufacturers to ensure optimal performance and longevity of the transmission system. During these maintenance procedures, it’s advisable to have your tranny tubes inspected for any signs of wear, damage, or clogging.

If the tranny tubes appear compromised, replacing them can prevent further issues and ensure that fresh, clean transmission fluid can circulate freely throughout the system. Neglecting to replace worn or clogged tranny tubes can lead to inadequate lubrication, increased wear on transmission components, and potentially costly repairs or even complete transmission failure.

Types of Tranny Tubes

Tranny tubes come in various materials, each with its own unique properties and applications. Understanding the different types can help you select the most suitable option for your vehicle’s specific needs and operating conditions.

PTFE (Polytetrafluoroethylene) Tranny Tube

PTFE, commonly known as Teflon, is a popular choice for tranny tubes due to its excellent heat and chemical resistance. These tubes are highly flexible, making them ideal for accommodating engine movement and vibration, while their smooth inner surface facilitates efficient fluid flow.

Key Features of PTFE Tranny Tubes:

- Excellent heat resistance, capable of withstanding temperatures up to 500°F (260°C)

- Highly resistant to chemicals found in transmission fluids

- Flexible and durable construction

- Smooth inner surface for optimal fluid flow

- Commonly used as original equipment manufacturer (OEM) components

PTFE tranny tubes are a popular choice for demanding applications, high-performance vehicles, and environments where extreme temperatures or harsh operating conditions are a concern.

PVC (Polyvinyl Chloride) Tranny Tube

PVC tranny tubes offer an economical alternative to PTFE, making them a cost-effective option for budget-conscious vehicle owners or applications with less extreme operating conditions.

Key Features of PVC Tranny Tubes:

- Lower cost compared to PTFE or stainless steel options

- Good chemical resistance to most transmission fluids

- Flexible construction, but less durable than PTFE

- Temperature resistance up to 200°F (93°C)

- Suitable for shorter fluid line runs or less extreme environments

Stainless Steel Tranny Tube

For extreme durability and high-performance applications, stainless steel tranny tubes are often the preferred choice. While not as flexible as PTFE or PVC options, these rigid tubes offer unparalleled strength and resistance to heat, chemicals, and abrasion.

Key Features of Stainless Steel Tranny Tubes:

- Exceptional durability and longevity

- Resistant to high temperatures, chemicals, and abrasion

- Rigid construction, ideal for precise routing

- Commonly used in high-performance vehicles or as replacements for hardline sections

- Corrosion-resistant, ensuring long-lasting performance

Stainless steel tranny tubes are often employed in motorsports applications, heavy-duty vehicles, or as replacements for rigid metal lines in areas prone to vibration or movement, reducing the risk of cracking or leaking over time.

Selecting the Right Tranny Tube

With various types of tranny tubes available, selecting the appropriate one for your vehicle is crucial to ensure optimal performance, reliability, and longevity. Here are some key factors to consider when choosing the right tranny tube:

How to Choose the Proper Tranny Tube?

- OEM Specifications: Consult your vehicle’s owner’s manual or consult with a professional mechanic to determine the recommended tranny tube specifications for your specific make, model, and year.

- Operating Conditions: Consider the operating environment and conditions your vehicle is subjected to, such as extreme temperatures, high vibration levels, or exposure to harsh chemicals.

- Transmission Fluid Compatibility: Ensure that the tranny tube material you select is compatible with the type of transmission fluid used in your vehicle to prevent premature degradation or chemical reactions.

- Routing and Length: Assess the routing requirements and measure the length needed to ensure proper fit and installation without excessive bending or kinking, which can restrict fluid flow.

Tranny Tube Size

Selecting the correct inner diameter for your tranny tube is essential to ensure proper fluid flow rate and prevent issues such as restriction or leakage. Undersized tubes can restrict fluid flow, leading to inadequate lubrication and potential transmission damage, while oversized tubes may not create a proper seal, resulting in leaks.

It is crucial to match the tranny tube inner diameter to the original equipment manufacturer (OEM) specifications for your vehicle’s transmission system. Consult your owner’s manual or a professional mechanic to determine the correct size for your application.

Kind of Tube

The type of tranny tube material you choose should be based on factors such as performance needs, operating environment, and budget considerations. Here’s a quick overview of the most common options:

- PTFE (Teflon): Excellent heat and chemical resistance, flexible, and durable, but more expensive.

- PVC: Cost-effective option with good chemical resistance, but lower heat tolerance and durability.

- Stainless Steel: Rigid but extremely robust, ideal for high-performance applications or hardline replacements.

Consider the specific requirements of your vehicle and choose the material that offers the best balance of performance, durability, and cost-effectiveness.

Flexibility of Tube

The flexibility of the tranny tube you select should be determined by the routing requirements and the level of movement or vibration your transmission system experiences. Here are some key considerations:

- Flexible Tubes: Allow for easier installation and can accommodate engine movement and vibration more effectively. However, they should be routed carefully to avoid excessive bending or kinking, which can restrict fluid flow.

- Rigid Tubes: Stainless steel or other rigid tubes may be necessary for precise routing or in areas with limited space. They can withstand more significant vibration without deforming but may require careful bending during installation to prevent kinks or cracks.

Evaluate your vehicle’s specific needs and choose the level of flexibility that best suits your application while ensuring proper fluid flow and preventing leaks or damage.

How to Use Tranny Tubes?

Proper installation and maintenance of tranny tubes are essential to ensure their longevity and the overall health of your vehicle’s transmission system. Here are step-by-step instructions for using tranny tubes effectively:

- Drain Transmission Fluid: Before working on the transmission system, ensure that you drain the existing transmission fluid according to your vehicle’s maintenance guidelines.

- Disconnect Old Tubes: Carefully disconnect the old tranny tubes from their connection points, taking note of their routing and positioning for reference during the installation of the new tubes.

- Route and Secure New Tubes: Carefully route the new tranny tubes through the designated paths, ensuring they are not kinked, twisted, or excessively bent. Secure the tubes using appropriate clamps or mounting hardware to prevent movement or chafing.

- Reconnect Tube Ends: Attach the new tranny tubes to their respective connection points, ensuring a tight and secure fit. Use clamps or other recommended hardware to create a leak-proof seal.

- Refill Transmission with New Fluid: Once the new tranny tubes are installed, refill the transmission system with fresh, high-quality transmission fluid according to your vehicle’s specifications.

- Inspect and Test: After completing the installation, inspect the entire system for any leaks or potential issues. Start the vehicle and allow it to reach operating temperature, then check for proper fluid flow and transmission operation.

- Periodic Inspections: Regularly inspect the tranny tubes for signs of wear, damage, or leaks during routine maintenance intervals. Replace them as needed to maintain the integrity of your transmission system.

Following these steps and adhering to proper installation and maintenance procedures will help ensure the longevity and optimal performance of your tranny tubes and transmission system.

Some Other Benefits of Tranny Tubes

While the primary function of tranny tubes is to facilitate fluid circulation and prevent leaks within the transmission system, these versatile components offer several additional benefits:

- Neat Routing: Tranny tubes allow for flexible and organized routing of fluid lines, enabling mechanics and DIY enthusiasts to navigate complex engine compartments and create a tidy, professional-looking installation.

- Easier Repairs and Maintenance Access: By using tranny tubes instead of rigid metal lines, it becomes easier to access and remove components for repairs or maintenance without having to disconnect and reshape hardlines.

- Cost-Effective Alternative: Replacing tranny tubes is often more cost-effective than replacing entire sections of rigid metal lines, especially in cases of damage or corrosion.

- Reduced Metal Line Corrosion: Over time, metal transmission lines can corrode due to exposure to various elements, leading to potential leaks or failures. Tranny tubes, particularly those made of corrosion-resistant materials like PTFE or stainless steel, can help mitigate this issue.

- Vibration Absorption: The flexible nature of tranny tubes allows them to absorb and accommodate engine vibrations, reducing stress on other transmission components and potentially extending their lifespan.

- Customization Opportunities: For enthusiasts or those modifying their vehicles, tranny tubes offer versatility in routing and installation, enabling custom setups or modifications that might be challenging with rigid metal lines.

By understanding these additional benefits, vehicle owners and mechanics can appreciate the true value of tranny tubes beyond their primary function, further reinforcing their importance in maintaining a healthy and efficient transmission system.

When is a Tranny Tube Used Most Effectively?

While tranny tubes are essential components in any transmission system, there are certain situations where their use becomes particularly beneficial or even crucial:

- Vehicles with High Vibration or Movement: In vehicles subjected to significant vibration or movement, such as off-road vehicles, performance cars, or heavy-duty trucks, tranny tubes are invaluable in accommodating these forces and preventing rigid lines from cracking or breaking.

- High Heat Environments: In applications where the transmission system operates under extreme heat conditions, such as in performance vehicles or heavy-duty equipment, tranny tubes made from heat-resistant materials like PTFE or stainless steel are essential to prevent fluid degradation or line failures.

- Custom or Modified Transmission Setups: When modifying or customizing a transmission system, tranny tubes offer the flexibility required for unique routing and installation, enabling enthusiasts to create bespoke setups tailored to their specific needs.

- Preventative Maintenance for Aging Vehicles: As vehicles age, their rigid metal transmission lines become more susceptible to corrosion, wear, and potential failure. Replacing these lines with tranny tubes can be an effective preventative maintenance measure, extending the lifespan of the transmission system and preventing costly repairs.

- Extreme Operating Conditions: In environments with harsh chemicals, high levels of abrasion, or other extreme operating conditions, tranny tubes constructed from durable materials like PTFE or stainless steel can withstand these challenges and maintain the integrity of the transmission system.

Is It Safe To Use Tranny Tubes?

Absolutely! When properly selected, installed, and maintained, tranny tubes are a safe and reliable component of your vehicle’s transmission system. However, it’s essential to follow some best practices to ensure their safe and effective use:

- Proper Material Selection: Choose tranny tubes made from materials compatible with your vehicle’s transmission fluid and operating conditions. PTFE, PVC, and stainless steel are commonly used and offer different levels of heat, chemical, and abrasion resistance.

- Correct Sizing: Ensure that the inner diameter of the tranny tube matches the OEM specifications for your transmission system. Undersized tubes can restrict fluid flow, while oversized ones may leak or fail to create a proper seal.

- Secure Routing and Installation: Carefully route and secure tranny tubes according to the manufacturer’s instructions, avoiding excessive bending, kinking, or contact with hot surfaces or moving parts that could cause damage or wear.

- Periodic Inspections: Regularly inspect tranny tubes during routine maintenance intervals for signs of wear, cracks, or leaks. Replace them promptly if any issues are detected to prevent potential transmission failures.

- Use Recommended Clamps and Fittings: Always use the appropriate clamps, fittings, and connection hardware recommended by the manufacturer or specified for your vehicle to ensure proper sealing and prevent leaks.

- Follow Manufacturer Guidelines: Consult your vehicle’s owner’s manual or consult with a professional mechanic to ensure you are following the recommended procedures and guidelines for tranny tube installation and maintenance specific to your make and model.

By adhering to these best practices, tranny tubes can be safely and effectively used to maintain the health and longevity of your vehicle’s transmission system. Remember, prevention and proper maintenance are key to avoiding costly repairs or failures down the line.

Six Most-Used Tranny Tubes

In the world of tranny tubes, certain products stand out as popular choices among mechanics and vehicle owners due to their quality, versatility, and reputation. Here are six of the most widely used and highly regarded tranny tubes on the market:

- Gates Tranny Tube

- Material: PTFE (Teflon)

- Features: Highly flexible, chemical and heat resistant, smooth inner surface

- Common Applications: OEM replacements, high-performance vehicles, custom builds

- Goodyear Tranny Tube

- Material: PVC

- Features: Cost-effective, good chemical resistance, flexible

- Common Applications: Budget-friendly replacements, general repairs

- Duratuff Stainless Steel Tranny Tube

- Material: Stainless Steel

- Features: Extreme durability, corrosion resistance, rigid construction

- Common Applications: High-performance vehicles, hardline replacements

- Viair Tranny Tube

- Material: PTFE (Teflon)

- Features: Reinforced construction, heat and chemical resistant, smooth inner bore

- Common Applications: Heavy-duty vehicles, high-heat environments

- ACDelco Tranny Tube

- Material: PTFE (Teflon)

- Features: OEM quality, flexible, compatible with various transmission fluids

- Common Applications: GM vehicle replacements, general repairs

- Neoform Stainless Steel Tranny Tube

- Material: Stainless Steel

- Features: Abrasion-resistant, high-temperature tolerant, rigid construction

- Common Applications: Race cars, high-performance builds, hardline replacements

These popular tranny tube options cover a wide range of materials, features, and applications, ensuring that vehicle owners and mechanics can find the right solution for their specific needs, whether it’s a budget-friendly repair, high-performance upgrade, or heavy-duty application.

Remember, when selecting and installing tranny tubes, always consult your vehicle’s manufacturer recommendations, follow proper installation procedures, and prioritize safety and compatibility to ensure optimal performance and longevity of your transmission system.

Final Words Tranny Tubes

Tranny tubes play an essential role in keeping your vehicle’s transmission system running smoothly. From facilitating fluid flow to preventing leaks and dissipating heat, these flexible conduits are vital components. Understanding the different types, materials, and proper selection criteria ensures you choose the right tranny tube for your needs. Correct installation and periodic inspection are crucial for maintaining their integrity.

While often overlooked, tranny tubes prevent costly repairs by accommodating engine vibrations and protecting rigid lines. Whether you’re a DIY enthusiast or professional mechanic, mastering tranny tube knowledge safeguards your transmission’s performance and longevity. Don’t underestimate the importance of these small but mighty tubes in your vehicle’s health.